|

| BIOLOGICS

|

Ultrasonic Homogenizer Series

(Sonicators)

|

|

|

|

For

over

five

decades,

BioLogics

laboratory

equipment

has

been

setting

new

standards

for

For

over

five

decades,

BioLogics

laboratory

equipment

has

been

setting

new

standards

for

design

innovation,

performance,

and

reliability.

The BioLogics family of Ultrasonic

Homogenizers offer precision engineering with all the The BioLogics family of Ultrasonic

Homogenizers offer precision engineering with all the

features

necessary to create a total system for ultrasonic disruption.

The

Ultrasonic Homogenizers can disintegrate most cells, bacteria,

spores or tissue.

The

Ultrasonic Homogenizers can disintegrate most cells, bacteria,

spores or tissue.

They can prepare an emulsion down to 1/100 of a micron

homogenize "immiscible" liquids,

They can prepare an emulsion down to 1/100 of a micron

homogenize "immiscible" liquids,

accelerate enzymatic and chemical reactions,

stimulate bacterial activity, disperse solids in

liquids and degas liquids

|

|

|

|

| Features

|

| How it Works :

|

•

The ultrasonic power supply transforms line voltage to high frequency 20 kHz electrical energy.

•

This electrical energy is transmitted to the probe where it is converted to mechanical energy.

•

The vibrations from the probe are coupled to and intensified by the titanium tip.

•

The probe vibrates in a longitudinal direction and transmits this motion to the titanium tip immersed in the solution.

•

Cavitation results, in which microscopic vapor bubbles are formed momentarily and implode, causing powerful

infinitesimal shock waves to radiate throughout the solution in proximity to the radiating face of the tip.

|

|

Contact

vs.

Non-Contact

Homogenization

Methods

|

|

|

The

CONTACT

homogenization

is

the

most

common

method

of

processing

a

sample.

The

probe

is

immersed

into

the

sample

where

the

radiating

face

of

the

probe

causes

the

sample

to

cavitate,

quickly

processing

the

sample.

Small

diameter

probes

such

as

the

Stepped

and

Tapered

Micro

tips

generate

high

intensity

cavitation

and

are

utilized

when

processing

small

volume

samples.

Large

diameter

probes

such

as

the

Solid

and

Tapped

tips

generate

low

intensity

cavitation

and

are

utilized

when

processing

large

volume

samples.

|

|

The

NON-CONTACT

homogenization

method

is

utilized

when

processing

small

volume

samples

where

the

probe

does

not

contact

the

sample.

This

method

is

sometimes

referred

to

as

a

“high

intensity

ultrasonic

bath”.

The

cavitation

within

the

water

processes

the

micro

tubes

or

vessels

which

are

suspended

during

processing.

Non-contact

method

is

most

effective

for

volumes

less

than

250

μl

as

foaming

or

sample

loss

are

eliminated.

In

addition,

this

method

ensures

that

sterile

or

pathogenic

samples

are

not

aerosolized

preventing

cross

contamination

|

| Automatic Tuning :

|

|

All the of our Ultrasonic Homogenizers models employ a propriety feedback system,

insuring that the generator is always working at it

maximum efficiency regardless of the

application. There is no need for constant adjustment by the operator.

The percentage of ultrasonic power emitted is indicated by the output LED meter,

enabling accurate reproducible results. |

|

| Applications :

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Accelerate Enzymatic Reactions

|

- Accelerate Chemical Reactions

|

- Stimulate Bacterial Activity

|

|

|

|

|

|

| Models

|

|

Catalogue

number

:

0-121-0002 Catalogue

number

:

0-121-0002

|

|

|

Descriptions

The Model 150V/T Ultrasonic

Homogenizer offers precision engineering with all the features necessary

to

create a total system for 150 watts of ultrasonic disruption.

Functions

PULSER POWER MODE – This allows the sample to be processed at full power while

limiting

temperature

increase and is essential for heat sensitive

samples.

CONSTANT POWER MODE – Selectable for non-heat critical sample

applications.

With

0-100%

Amplitude

(Power)

control,

the

operator

can

optimize

the

titanium

probe’s

intensity

to

efficiently

process

the

sample.

TIMER – 1 to 15 minutes

|

|

includes:

-

ultrasonic generator

- transducer assembly

- stainless steel

transducer post

- laboratory clamp

- 3 prong transducer clamp

- pair of pin

wrenches

|

|

Specifications |

|

PROCESSING VOLUME

|

250 µl - 300 ml |

TIMER

|

1 - 15 MINUTES |

|

MAX. TIP DIAMETER

|

1/2" (12.7mm) |

PULSER

|

10 - 90% |

|

POWER OUTPUT

|

0 - 150 WATTS |

DISPLAY TYPE

|

LED

|

|

OUTPUT FREQUENCY

|

20 kHz |

MICRO

PROCESSING

CONTROL

|

N/A

|

|

AUTOMATIC TUNING

|

YES |

|

OPTIONAL

|

|

|

|

|

Catalogue

number

:

0-122-0002 Catalogue

number

:

0-122-0002

|

|

|

Descriptions

The Model 300V/T Ultrasonic

Homogenizer offers precision engineering with all the features necessary

to

create a total system for 300 watts of ultrasonic disruption.

Functions

PULSER POWER MODE – This allows the sample to be processed at full power while

limiting

temperature

increase and is essential for heat sensitive

samples.

CONSTANT POWER MODE – Selectable for non-heat critical sample

applications.

With

0-100%

Amplitude

(Power)

control,

the

operator

can

optimize

the

titanium

probe’s

intensity

to

efficiently

process

the

sample.

TIMER – 0 to 15 minutes

|

|

includes:

-

ultrasonic generator

- transducer assembly

- stainless steel

transducer post

- laboratory clamp

- 3 prong transducer clamp

- pair of pin

wrenches

|

|

Specifications |

|

PROCESSING VOLUME

|

250 µl - 2000 ml |

TIMER

|

1 - 15 MINUTES |

|

MAX. TIP DIAMETER

|

1" (25.4mm)/Cup

Tip |

PULSER

|

10 - 90% |

|

POWER OUTPUT

|

0 - 300 WATTS |

DISPLAY TYPE

|

LED

|

|

OUTPUT FREQUENCY

|

20 kHz |

MICRO

PROCESSING

CONTROL

|

N/A

|

|

AUTOMATIC TUNING

|

YES |

|

OPTIONAL

|

|

|

|

|

Catalogue

number

:

0-127-0002 Catalogue

number

:

0-127-0002

|

|

|

Descriptions

The Ultrasonic 3000 Ultrasonic

Homogenizer delivers 300 watts of ultrasonic disruption and includes

an

integrated Sound Abating Chamber to reduce cavitational sound emitted during

processing.

The clear door permits viewing of the sample while processing. An access port

for cables and tubing

is also provided for use with Cup Tips and the Continuous

Flow Chamber

Functions

PULSER POWER MODE – This allows the sample to be processed at full power while

limiting

temperature

increase and is essential for heat sensitive

samples.

CONSTANT POWER MODE – Selectable for non-heat critical sample

applications.

With

0-100%

Amplitude

(Power)

control,

the

operator

can

optimize

the

titanium

probe’s

intensity

to

efficiently

process

the

sample.

TIMER – 0 to 15 minutes

|

|

includes:

-

sound abating chamber with adjustable height sample table

- transducer assembly

-

pair of pin wrenches

|

|

Specifications |

|

PROCESSING VOLUME

|

250 µl - 2000 ml |

TIMER

|

1 - 15 MINUTES |

|

MAX. TIP DIAMETER

|

1" (25.4mm)/Cup

Tip |

PULSER

|

10 - 90% |

|

POWER OUTPUT

|

0 - 300 WATTS |

DISPLAY TYPE

|

LED

|

|

OUTPUT FREQUENCY

|

20 kHz |

MICRO

PROCESSING

CONTROL

|

N/A

|

|

AUTOMATIC TUNING

|

YES |

|

INTEGRATED

|

|

|

|

|

Catalogue

number

:

0-128-0002 Catalogue

number

:

0-128-0002

|

|

|

Descriptions

3000MP Ultrasonic Homogenizer delivers 300 watts of ultrasonic

disruption with precision control from

a microprocessor and a graphical user

interface displayed on a large bright 5.7" (145 mm) LCD display.

The integrated Sound Abating Chamber reduces cavitational sound emitted

during sample processing.

The clear door permits viewing of the sample while

processing. An access port for cables and tubing is

also provided for use with

Cup Tips and the Continuous Flow Chamber.

With

0-100%

Amplitude

(Power)

control,

the

operator

can

optimize

the

titanium

probe’s

intensity

to

efficiently

process

the

sample.

Functions

MANUAL MODE – the user defines

the AMPLITUDE, can enable the PULSER feature, and monitor sample temperature

during processing.

PROGRAM MODE – the user can define, store, and recall up to 10 programs.

Within each PROGRAM,

the AMPLITUDE, PULSER parameters, TEMPERATURE settings for

COOL DOWN

and SHUT DOWN temperatures,

can be defined and stored.

MACRO MODE

– the user to assemble up to 8 sequences using any of the

10 stored PROGRAMS with

an optional user defined time delay, from 1 secs to 99

hrs, between each sequence.

|

|

includes:

-

Ultrasonic generator with

integrated sound abating

chamber with adjustable

height sample table

- transducer assembly

- temperature probe

-

pair of pin

wrenches

|

|

Specifications |

|

PROCESSING VOLUME

|

250 µl - 2000 ml |

TIMER

|

1

SEC - 99

HOURS |

|

MAX. TIP DIAMETER

|

1" (25.4mm)/Cup

Tip |

PULSER

|

1

SEC - 1

HOUR |

|

POWER OUTPUT

|

0 - 300 WATTS |

DISPLAY TYPE

|

5.7” (145mm)GLCD

|

|

OUTPUT FREQUENCY

|

20 kHz |

MICRO

PROCESSING

CONTROL

|

YES

|

|

AUTOMATIC TUNING

|

YES |

|

INTEGRATED

|

|

|

|

|

|

|

|

| Probe

Tips & Accessories

|

| Micro

Tip

Probes

300

μl

to

25

ml

Sample

Volumes

|

|

Micro Tips are

narrow

and

long

probes

which

generate

high

intensity

cavitation

for

processing

small

sample volumes.

The

Stepped

Micro

Tip

probe

is

coupled

directly

to

the

Transducer.

The

Tapered

Micro

Tip

probes

are

threaded

to

the

1/2”

(12.7

mm)

Tapped

Tip

probe

(0-120-0010)

then

coupled

to

the

Transducer.

|

|

|

|

Solid

Tip

Probes

5

ml

to

2000

ml

Sample Volumes

|

| Solid

Tip

probes

are

manufactured

from

a

titanium

alloy

and

machined

to

a

specific

diameter

and

shape.

When

coupled to

the

Transducer,

the

probe

is

driven

to

its

resonant

frequency,

causing

the

probe

to

expand

and contract

longitudinally.

When

the

probe

is

immersed

into

a

liquid

sample,

the

cavitation

formed

processes

the

sample.

Solid

Tip

probes

should

be

utilized

when

processing

liquids

containing

organic

solvents

or

high

surface

tension

samples.

In

addition,

Solid

Tip

probes

are

machined

from

one

solid

titanium

piece

and

less

likely

to

cause

sample cross

contaminations. Sample

volume

is

determined

by

the

tip

diameter.

Smaller

diameter

probes

generate

high intensity

cavitation

in

a

small

focused

area,

ideal

for

small

sample

volumes.

Larger

diameter

probes

generate

low intensity

cavitation

in

a

broader

area,

ideal

for

larger

sample

volumes.

The

radiating

face

or

flat

portion

of

the

probe will

pit

or

erode

in

time

and

should

be

replaced

when

worn.

Probe

performance

degrades

in

proportion

to

the

degree

of

erosion

or

pitting

which

occurs

at

the

tip

surface,

until

a

point

is

reached

where

the

level

of

energy

transmitted

in

the

sample

is

significantly

lessoned.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SOLID

|

SOLID

|

SOLID

|

SOLID

|

|

|

|

| Tapped

Tip

Probes

10

ml

to

2000

ml

Sample

Volumes

|

| Tapped

Tip

probes

are

a

2

piece

design

comprised

of

the

Body

and

Flat

Tip,

both

manufactured

from

a

titanium

alloy

and

machined

to

a

specific

diameter

and

shape.

The

body

has

a

threaded

end

allowing

the

flat

tip

to

be

replaced.

The

flat

tip

or

radiating

face

will

pit

or

erode

in

time

and

should

be

replaced

when

worn.

Probe

performance

degrades

in

proportion

to

the

degree

of

erosion

or

pitting

which

occurs

at

the

tip

surface,

until

a

point

is

reached

where

the

level

of

energy

transmitted

in

the

sample

is

significantly

lessoned. Tapped

Tip

probes

are

NOT

recommended

when

processing

liquids

containing

organic

solvents

or

high

surface

tension

samples.

Utilizing

Tapped

Tip

probes

with

such

samples

are

likely

to

cause

sample

cross

contaminations.

|

|

|

|

Extender

Tip

Probes

Solid

and

Tapped

|

| Extender

Tips

are

utilized

to

extend

the

length

of

a

probe

to

reach

into

long

necked

vessels.

They

attach

to

the

corresponding

diameter

Tapped

Tip

probes

and

generally

increase

the

overall

length

by

5” (127

mm).

Extender

Tips

offer

the

same

sample

volume

and

amplitude

as

their

corresponding

diameter

Tapped

Tip

probes.

Extender

Tips

are

available

in

Solid

to

Tapped

configurations.

Tapped

Extender

Tips

use

the

corresponding

diameter

replacement

Flat

Tips.

|

|

|

|

|

Titanium Solid Extender Tips

|

Titanium Tapped Extender Tips

|

|

|

|

|

|

Catalog No.

|

|

|

|

|

|

|

|

TIP DIA.(MM)

|

|

|

|

|

|

|

|

LENGTH(CM)

|

|

|

|

|

|

|

|

TYPE

|

SOLID

|

SOLID

|

SOLID

|

|

|

|

|

|

|

| Flat

Tips

Replaceable

tips

for

Tapped

Tips

Probes

and

Tapped

Extender

Tips

|

| Tapped

Tip

and

Extender

Tip

probes

use

replaceable

Flat

Tips.

During

normal

use,

the

radiating

face

or

Flat

Tip

of

the

probes

erodes

and

becomes

less

effective

over

time.

Replace

Flat

Tips

with

corresponding

Tapped

Tip

or

Extender

Tip

diameter.

|

|

|

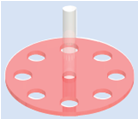

| CUP

Tips

|

| The

Cup

Tip

offers

non-contact

homogenization

of

small

volume

samples

in

a

high

intensity

ultrasonic

bath.

Samples

are

processed

in

sealed

tubes

or

vials

eliminating

aerosols

and

cross

contamination.

Multiple

tubes

or

vials

of

sterile

or

pathogenic

samples

can

be

processed

simultaneously.

The

titanium

probe

is

mounted

within

an

acrylic

body

where

the

body

is

filled

with

water.

Sample

tubes

or

vials

can

be

placed

in

the

tray

and

suspended

above

the

probe

during

processing.

The

cavitation

in

the

water

processes

the

tubes

or

vials.

During

sample

processing,

heated

is

generated,

so

inlets

with

barbed fittings

can

be

connected

to

cold

water

or

a

Chiller

to

maintain

temperature

and

water

level

within

the

acrylic

body.

|

|

|

|

|

|

|

|

|

0-120-0020

|

|

|

|

|

|

Chamber

Vol

|

250

ml

|

|

|

Intensity

|

Medium

|

|

|

|

|

| Continuous

Flow

Chamber

|

| The

Continuous

Flow

Chamber

permits

in

line

or

continuous

processing

of

large

volume

batch

samples.

Batch

sample

volumes

can

be

recirculated

through

the

chamber

multiple

times

for

desired

sample

results.

Samples

are

passed

through

the

chamber

using

one

of

the

two

bottom

inlets.

As

the

sample

flows

through

the cavitation

chamber,

the

sample

is

processed.

The

processed

sample

exits

the

chamber

through

the

two outlet

ports.

By

recirculating

the

sample,

adjusting

flow

rate

and

cavitation

intensity,

the

desired

results

can

be

achieved.

During

sample

processing,

heated

is

generated

by

the

probe.

Connecting

the

integrated

cooling

jacket

to

a

cold

water

source

or

Chiller,

will

maintain

sample temperature

during

processing.

|

|

|

|

Catalog No.

|

0-120-0026

|

|

|

Material

|

Stainless

Steel

|

|

Oper

Pressure

|

20

psi

|

|

Internal

Vol

|

35

ml

|

|

*

REQUIRES

THE

3/4”

(19.1

mm)

DIAMETER

SOLID

TITANIUM

TIP

CATALOG

NO.

0-120-0013

|

|

|

|

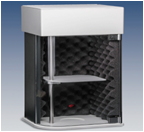

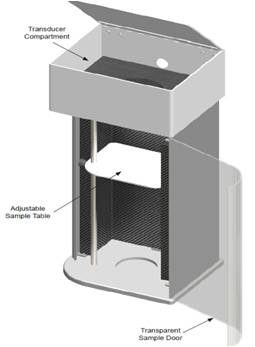

| SONABOX

Sound

Abating

Chamber

|

| The

SONABOX

sound

abating

chamber

reduces

cavitational

sound

emitted

during

processing

when

used

in

conjunction

with

the

Model

150VT

and

300

VT

Ultrasonic

Homogenizers.

Harmonics

are

produced

by

the

vessel

walls

and

fluid

surface,

and

can

be

discomforting

to

the

user

with

extended

operation.

The

SONABOX

reduces

the

harmonics

by approximately

20-25

dBa.

The

clear

acrylic

door

permits

viewing

of

the

sample

while

protecting

the

operator

against

accidental

splashing.

The

height

of

the

sample

table

can

be

adjusted

to

vessel

size

and

shape.

Access

ports

for

cables

and

tubing

are

also

provided

for

use

with

the

Cup

Tip

or

Continuous

Flow

Chamber

|

|

|

|

Catalog No.

|

0-125-0001

|

|

|

Sample

Table

|

Adjustable

Height

|

|

Chamber

Doo

|

Clear

Acrylic

Door

|

|

Cable

&

Tubing

Ports

|

2

|

|

Outside

|

26.7

cm

W

x

21.6

cm

D

x

59.7

cm

H

|

|

Inside

|

24.8

cm

W

x

19.7

cm

D

x

45.1

cm

H

|

|

|

|

|

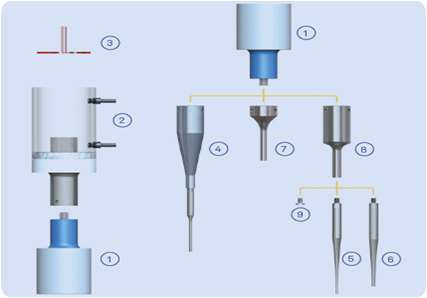

Small

Volume

Probe

Map

|

|

|

|

No.

|

VOLUME

|

DESCRIPTION

|

CATALOG

NO

|

|

①

|

-

|

Transducer

|

2-122-0010

|

|

②

|

Based

on

tube

vol

|

Cup

Tip

|

2-122-0019

|

|

③

|

-

|

Microtube

Tray

|

2-120-0021

|

|

④

|

300ul~15ml

|

5/32"(3.9mm)Stepped

Micro

Tip

|

2-120-0005

|

|

⑤

|

250ul~10ml

|

1/8"(3.2mm)

Tapered

Micro

Tip

|

2-120-0007

|

|

⑥

|

750ul~25ml

|

3/16"(4.8mm)Tapered

Micro

Tip

|

2-120-0008

|

|

⑦

|

5ml~200ml

|

3/8"(9.5mm)Solid

Tip

|

2-120-0009

|

|

⑧

|

10ml~300ml

|

1/2"(12.7mm)Tapered

Tip

|

2-120-0010

|

|

⑨

|

|

1/2"(12.7mm)Flat

Tip

|

2-120-0016

|

|

|

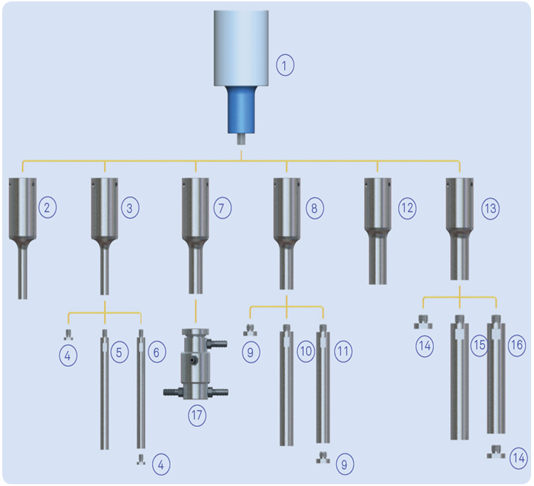

Large

Volume

Probe

Map

|

|

|

|

No.

|

VOLUME

|

DESCRIPTION

|

CATALOG

NO

|

|

①

|

-

|

Transducer

|

2-122-0010

|

|

②

|

10ml~300ml

|

1/2"(12.7mm)Solid

Tip

|

2-122-0011

|

|

③

|

10ml~300ml

|

1/2"(12.7mm)Tapped

Tip

|

0-120-0010

|

|

④

|

-

|

1/2"(12.7mm)Flat

Tip

|

2-120-0016

|

|

⑤

|

10ml~300ml

|

1/2"(12.7mm)Solid

Extender

Tip

|

0-120-0032

|

|

⑥

|

10ml~300ml

|

1/2"(12.7mm)Tapped

Extender Tip

|

2-122-0033

|

|

⑦

|

25ml~600ml

|

3/4"(19.1mm)Solid

Tip

|

0-120-0013

|

|

⑧

|

25ml~600ml

|

3/4"(19.1mm)Tapped

Tip

|

2-122-0012

|

|

⑨

|

-

|

3/4"(19.1mm)Flat

Tip

|

0-120-0017

|

|

⑩

|

25ml~600ml

|

3/4"(19.1mm)Solid

Extender

Tip

|

2-122-0016

|

|

⑪

|

25ml~600ml

|

3/4"(19.1mm)Tapped

Extender

Tip

|

0-122-0016

|

|

⑫

|

50ul~2000ml

|

1"(25.4mm)

Solid

Tip

|

2-122-0015

|

|

⑬

|

50ul~2000ml

|

1"(25.4mm)

Tapped Tip

|

0-122-0014

|

|

⑭

|

-

|

1"(25.4mm)

Flat

Tip

|

2-122-0018

|

|

⑮

|

50ul~2000ml

|

1"(25.4mm)

Solid

Extender

Tip

|

0-120-0036

|

|

⑯

|

50ul~2000ml

|

1"(25.4mm)

Tapped Extender

Tip

|

0-122-0037

|

|

⑰

|

0.25L/min

|

Continuous

Flow

Chamber

|

0-120-0026

|

|

|

|

|

|

|

|

SONABOX

Sound

Abating

Chamber

|

250ml

Cup

Tip

and

8

position

Micro

Tube

Tray

shown

attached

to

transducer

assembly

|

Continuous

Flow

Chamber

with

3/4'

Dia.

Solid

Titanium

Tip

and

Tranducer

assembly

|

|

|

|

|

|

|

|

|

|